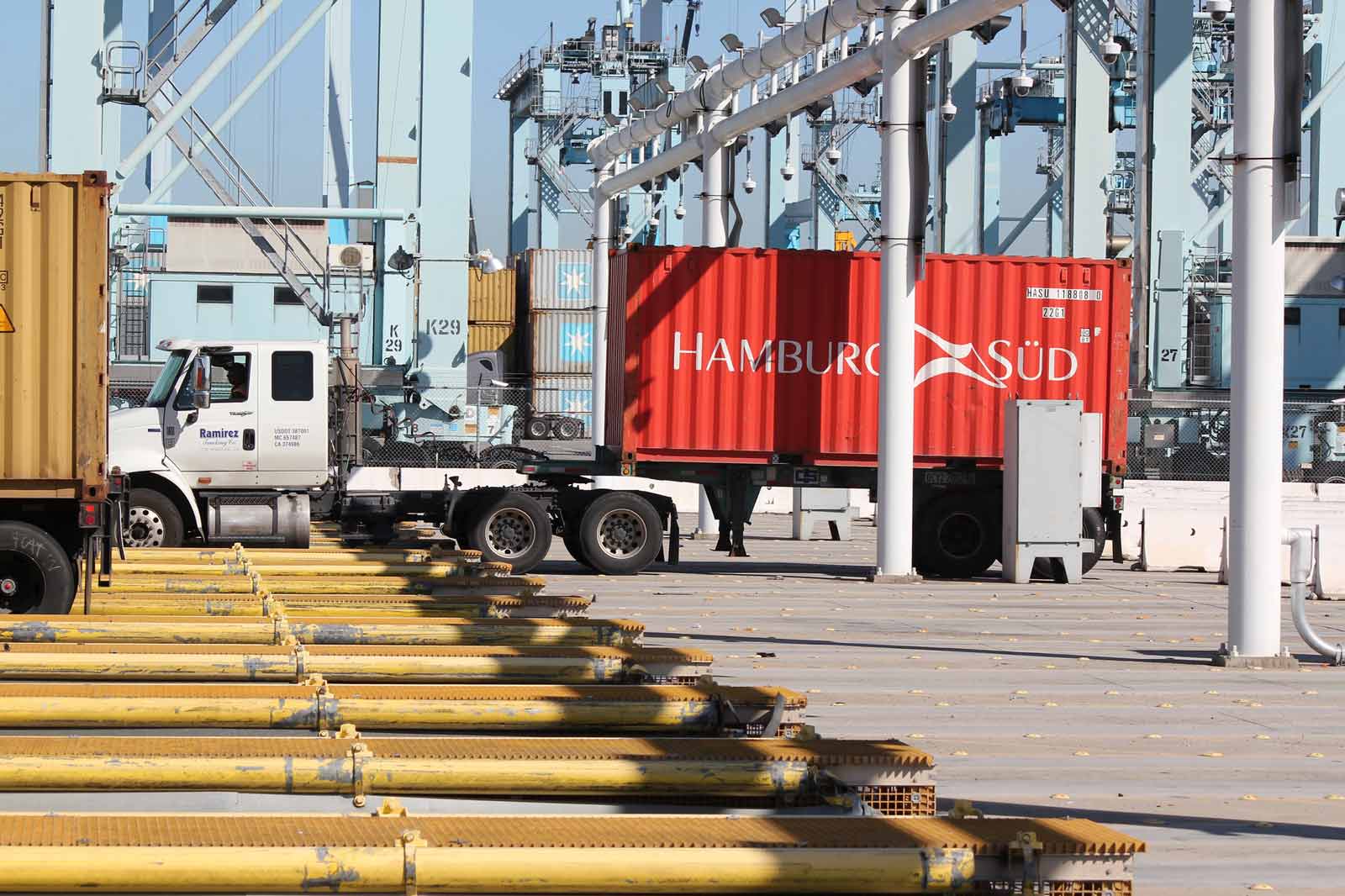

Gate Services

Our high-volume terminals, handling cargo surges from large ships, have adopted a number of processes and technologies to eliminate multiple handling of containers and reduce truck waiting times. We also offer the flexibility, on request, to handle requests outside of standard operating hours where these aren’t already 24/7.

Verified Gross Mass (VGM) Weighing

By working directly with APM Terminals for Verified Gross Mass (VGM) requirements, shippers can benefit from a one-stop-shop experience that is efficient and accurate without disrupting the supply chain.Most of our terminals and inland services facilities have certified and calibrated weighing facilities - this will not only save cost and time in obtaining the VGM for your container, but also improves supply chain flow and guarantees compliance with IMO regulations and local legislation. It also eliminates the risk of costly claims and re-weighing containers on request of authorities or shipping lines.

One-stop experience for VGM

- Containers can be delivered at the gate without VGM cut-off time.

- We take care of all your VGM weighing and submission requirements and load your cargo on the vessel.

- You provide us with data and deliver your container and we ensure that your VGM data is submitted and your cargo is on its way to the next destination.

Peel-off

Peel off addresses the problem of retrieving the desired container from a stack, by segregating the containers destined for a large beneficial cargo owner, or multiple BCOs, who agree to aggregate their containers into a single stack.

When a critical mass is achieved, usually on the second day after a ship arrives, the trucking company assigned to the job dispatches dozens of trucks to the terminal. Drivers enter the terminal and proceed immediately to the stack. The longshoreman uses a top-handler to peel off a container from the top of the stack and deliver it to the driver. The machine basically stays put in one spot and delivers one container after another to drivers as they arrive at the single stack. The driver proceeds to the designated off-dock yard, drops off the container, and returns to the terminal for the next load.

Peel off requires communication in real time among trucking companies, terminal operators and BCOs. Truckers dispatch their drivers only after they have been notified that the terminal has cleared and moved enough peel-off containers to the stack to allow a free flow of trucks into the facility. Drivers dray most of the containers to the off-dock yard and BCOs send their truckers to that site to move the containers to their distribution centres. Some of the containers, though, are drayed directly to the DCs.

A successful operation begins with the proper stowage of the vessel so the containers designated for the peel-off stack are grouped together on the vessel. Peel off addresses the “final- mile” problem that many BCOs say is adding time and cost to the delivery of their shipments.

Early Gate-In

Early gate in enables customers to deliver containers to Maasvlakte II at any time and store containers at the terminal itself, regardless of the normal permitted time frame. Customers are charge on a per day per container stored basis.

Early gate-in removes the need to first deliver some containers to an inland storage location, or to deliver them in separate shipments. Enabling customers to deliver all of their containers to the terminal in one go, even if part of the delivery is scheduled for a later date, reduces costs.

Removing the need to first deliver part of the shipment to an inland storage depot reduces logistics complexity, transport costs and storage costs. In fact, you have just one contact at APM Terminals to ensure your containers are shipped on time.

At a glance

- Increases efficiency and reduces costs

- Reduces supply-chain complexity

- Increases flexibility

- Reduces chance of error

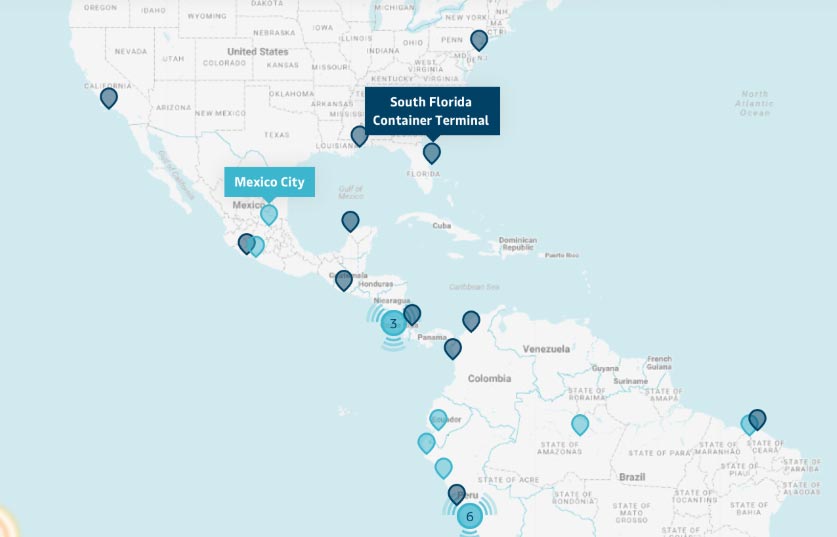

Service Locator

Use our interactive service locator to find out where we offer services around the world, or to discover what services are offered in a particular location.